OEM Vs. Third-Party Parts: Which Offer The Best Value? Cost, Quality & Performance Factors

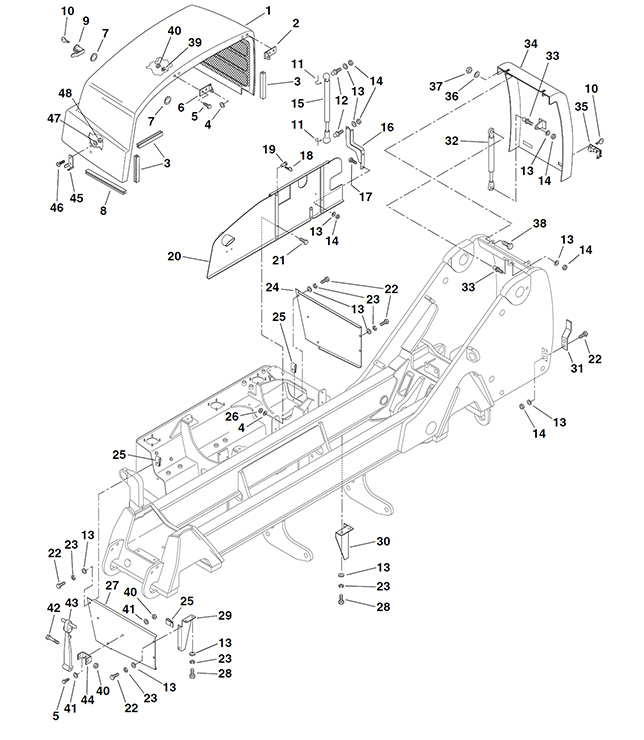

When it comes time to replace worn or damaged parts on your telehandler, boom lift or other heavy equipment, you'll inevitably face the choice between genuine Original Equipment Manufacturer (OEM) parts and cheaper aftermarket or third-party parts. However, there are compelling reasons to invest in OEM parts to maximize the performance, safety and longevity of your equipment. MJ Equipment experts are here to guide your OEM part selection. Contact us today!

Find Your Part3 Reasons to Buy OEM Parts Over 3rd Party Parts

-

OEM Parts Are Engineered Specifically for Your Equipment

OEM parts are engineered to integrate seamlessly with the other components in your make and model's design because they are designed by the same engineers who built your equipment. OEM parts go through rigorous testing and quality control to ensure they meet the equipment manufacturer's strict specifications for dimensions, materials and durability.

Aftermarket or third-party parts are reverse-engineered to mimic OEM parts’ functionality. However, these knock-off parts are unlikely to have the same precision engineering or advanced quality control. Using a "good enough" part rather than the genuine OEM part intended for your equipment compromises performance and safety down the line.

-

OEM Parts Preserve the Safety of Your Equipment

The heavy loads, high reaches and other demands placed on equipment like telehandlers and boom lifts make safety a top priority. Using genuine OEM replacement parts preserves the overall integrity and safety of your equipment's design. OEM parts are engineered with proprietary materials and treatments to handle intense jobsite conditions day after day. Parts like booms, chains, tires and hydraulics all have safety implications if they underperform or fail unexpectedly.

Aftermarket parts may look the same on the outside but could lack the necessary structural properties to operate safely in the toughest conditions. Don't compromise safety - insist on OEM parts manufactured to adhere to the equipment designer's high standards.

-

OEM Parts Come with Manufacturer Warranties

Replacing parts with genuine OEM components comes with the peace of mind of a manufacturer's warranty in many cases. OEM parts often come with a 6-12 month warranty protecting against defects in materials or workmanship.

Aftermarket parts usually have no warranty or a very limited warranty. If a critical part like a drivetrain or cylinder seal fails prematurely when using a knock-off part, you'll likely have to absorb the full cost and downtime of the failure. With OEM parts, the manufacturer will back their parts and share some of the burden.

OEM Vs. 3rd Party Value & Costs

The Value of Maintaining Optimal Equipment Performance

Your equipment relies on the balanced interactions between all its components to achieve rated capacities, speed, fuel efficiency and overall performance. Introducing an inferior quality aftermarket part into the system impedes performance in ways not immediately apparent.

An aftermarket hydraulic hose failing to meet OEM specifications for burst pressure may not fail immediately. However, it could lead to sluggish response times, lesser lift capacities and increased component wear. This slowly erodes the optimal performance you paid for from the equipment manufacturer.

Genuine OEM parts help maintain your equipment's performance parameters over the long haul. Don't leave money on the table with underperforming equipment caused by cut-rate parts.

The Value of Maintaining Optimal Equipment Performance

Your equipment relies on the balanced interactions between all its components to achieve rated capacities, speed, fuel efficiency and overall performance. Introducing an inferior quality aftermarket part into the system impedes performance in ways not immediately apparent.

An aftermarket hydraulic hose failing to meet OEM specifications for burst pressure may not fail immediately. However, it could lead to sluggish response times, lesser lift capacities and increased component wear. This slowly erodes the optimal performance you paid for from the equipment manufacturer.

Genuine OEM parts help maintain your equipment's performance parameters over the long haul. Don't leave money on the table with underperforming equipment caused by cut-rate parts.

The Value of Maintaining Optimal Equipment Performance

Your equipment relies on the balanced interactions between all its components to achieve rated capacities, speed, fuel efficiency and overall performance. Introducing an inferior quality aftermarket part into the system impedes performance in ways not immediately apparent.

An aftermarket hydraulic hose failing to meet OEM specifications for burst pressure may not fail immediately. However, it could lead to sluggish response times, lesser lift capacities and increased component wear. This slowly erodes the optimal performance you paid for from the equipment manufacturer.

Genuine OEM parts help maintain your equipment's performance parameters over the long haul. Don't leave money on the table with underperforming equipment caused by cut-rate parts.

Buy OEM Parts From Reputable MJ Equipment

Don't diminish the value of your equipment investment by using inferior aftermarket replacement parts. Insist on genuine OEM parts directly from MJ Equipment or an authorized dealer to maintain performance, safety and resale value over your equipment's lifetime. The minor upfront savings of cheaper third-party parts will never outweigh the long-term benefits of quality OEM components built specifically for your model.